|

| |

|

| |

Flexible Continuous Batch Washer solutions modified to fit your needs

Various complete CBW systems flexible enough to fit in every laundry

In this newsletter a selection of our CBWs is presented which can be combined with a set of dryers to meet every possible requirement as regards to capacity or layout of the system. TEXFINITY® has many years of experience in refurbishing and installing complete CBW systems. Due to our own range of control systems, we have the ability to modify used systems into a solution that is 100% meeting the requirements of your laundry. TEXFINITY® can combine existing systems in your laundry with CBW systems bought from our company. We can build systems from scratch, or expand your existing systems to increase capacity, add volume or reduce energy and increase efficiency.

The sytems presented below are a few of the possible combinations we have in stock. Take a look below, and contact us for more information on info@texfinity.com. Click on the links of the machines below to see more information and pictures, directly on our website and launch your inquiries easily.

This newsletter covers Continous Batch Washers from: LAVATEC, KANNEGIESSER, SENKING and MILNOR, the 4 major brands of CBWs. Futhermore combinations with PRESSES, CENTRIFUGES and DRYERS from the same brands.

|

Kannegiesser PowerTrans Classic

|

|

Kannegiesser CBW system from 2009, 10 compatments of 50kg.

This very nice CBW is in excellent condition and has been built in June 2009.

- 10 compartments of 50kg.

- CBW can be loaded with Bag system or Loading conveyor

- Combination with Senking Press or very Nice Kannegiesser Press

- Combination with shuttle and Dryers, gas or Steam heated Single or double batching

|

|

|

|

Lavatec BT

|

|

12 compartments 50kg CBW in excellent condition with maximum Flow diagram flexibility

The Lavatec batch washer has proven its place in the market for many years now. The ridgid and easy design make it a machine which is easy to maintain and flexible to use. Combined with either a press or a centrifuge, shuttle and several dryers, either steam or gas heated, this system can reach a capacity of up to 1300kg of dry linen per hour. The design allows for external adaptation and integration of heat and water recovery systems to built a system that keeps up with the latest environmental standards.

TEXFINTY has 2 of these systems in stock which can easily be integrated into a large capacity wash room set up, loaded with either Step conveyors or overhead bag systems.

Specifications:

- Lavatec LT12x50BT

- Bottom Transfer

- 12 compartments 50kg

- Year of constructio 1995 - rebuilt by Lavatec in 2005

|

|

|

|

Senking Universal

|

|

Senking CBW System with 9 compartments and 36kg batches, is in excellent condition.

The UNIVERSAL especially excels because of high-quality manufactured components. The core of the machine is its high-solid inner drum with its eccentric Archimedean helix.

All pipes, both for fresh and waste water are made of stainless steel as a standard feature.

The proven bath exchange technique with standing baths in the pre- and main-wash-zone is an important feature and condition for high flexibility and gives low operational costs. Different kinds of linen may be washed directly one after the other in this process.

Specifications:

- 9 compartments 35 kg

- Universal

- Loading with bag system (also available)

- Combination with Senking dryers and Shuttle

- Can be easiliy modified to fit in any laundry

|

|

|

|

Milnor Sectional

|

|

Compact Milnor CBW 5 compartments 50kg, with Centrifuge, from 2008

- Mentor® Control

- Flexible batch washer system, 5 compartments 50kg

- Including Cetrifuge

- Milnor Dryers, 50kg Gas Heated from 2008

- Loading with Bag system and Loading conveyor

- Shuttle and Gas heated dryers

- Top transfer for better mechanical action

- Year of construction 2008

|

|

|

|

Passat (Böwe) EP 860-35

|

|

This very nice Press has a capacity of 50kg and a pressure of 35 bar.

The press is in excellent conditon and has following features:

- Kannegiesser/Passat

- 50 kg Batches up to 35 Bar pressure max, programmable

- Cooler for oil-circuit temperature controlled.

- Computer control with soft-touch display for manual or automatic operation.

- 100 standard press programmes with freely programmable parameters for operation of the press strake, speed of descent, pressure build-up, pressure (0,8 - 3,5 Mpa).

- High pressure press time 2 - 90 sec. freely programmable for each programme.

- Proportional hydraulic valves ensure handling of all types of linen.

- Rapid ram descent, freely programmable to a) batch height b) linen contact height

- Year of Construction 2002

|

|

|

|

Senking Z770

|

|

SENKING CENTRIFUGE:

An increasing number of laundries are processing garments in a tunnel washing system. This puts a demand towards a low moisture retention and equal distribution of the moisture in order to feed the garments directly into a tunnel finisher. The textiles should be treated gently and the centrifugal extractor should keep up with the capacity of the tunnel washer even at short cycle times. The major advantage of centrifugal extractors compared to presses is a higher extraction performance for many synthetic fibres, e.g. for workwear or floormats.

- High G-force drum

- Capacity 72kg

- G-Force: up to 800G

- Asynchronous controlled drive motor: 18 kW

- Electronic braking with current regeneratioin back into the local net

- Unbalacing Sensors

- Year of construction: 2001

|

|

|

|

Kannegiesser D60 G-WU-R-B-IR

|

|

More than 50 dryers in stock, ranging capacities from 50kg to 270kg, Gas or Steam heated

brands LAVATEC, SENKING, KANNEGIESSER, PASSAT, all possible to combine with the CBWs listed above or for expansion of your dryer capacity.

Several dryers available of different sizes, amogst them:

- Kannegiesser Gas Heated Dryers capacity (kg): 60 from 2012

- Kannegiesser Gas Heated Dryer from 2001 from 2001

- Lavatec TT735: 75Kg Steam Heated and Gas Heated

- Lavatec TT733: 50kg Gas heated and Steam Heated

- Passat 258.100: 100Kg Steam Heated

- Senking DTA: 50kg Steam Heated

- Senking DTA: 36kg Gas Heated or 50kg Steam Heated

|

|

|

Texfinity ALCBWCO

|

|

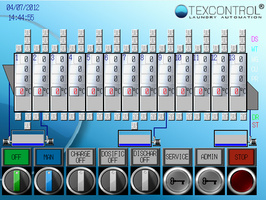

State of the art controller for all brands of CBWs and Dryers

Applying the TEXCONTROL Continuous Batch Washer control system empowers you to monitor and increase the production efficiency of your CBW. The 5.7, 8.4 or 10 inch touch screen makes it easy to operate and shows an instant clear overview screen with alarm or message text, recipe name, article and customer information. For the full range of controllers, click on this link: TEXMOTION CONTROLLERS

CBW Control Features:

- flexible for all CBW set ups

- loading via Step conveyor or Bagsystem

- interfaces with all brands of water extraction presses

- interfaces with many dryer controls, but seemless with the

- TEXCONTROL dryer control, adding more features

- detailed parameter view on one screen: temperature per

- compartment, weight, article, customer.

- integration of chemical dosing

- up to 99 different programs

- world wide component support

- interfaces with all CBW brands and mixes of brands

- internet connection for remote support

- can be integrated in TEXVIEW application

- competitive price

|

|

| |

|

| |

|

You are receiving this mailing because you subscribed to the Texfinity maillist.

To unsubscribe please click here.

You cannot reply to this e-mail. For more information send an e-mail to: info@texfinity.com

|

|