| |

In this newsletter we would like to emphasize on the tunnelfinishers and garmet folders Texfinity currently has available.

Since Tunnelfinishers, require a high level of customization, we are available to discuss the integration of the systems proposed in your laundry and combine the right machines.

We have a solution for every laundry, either gas heated or steam heated tunnelfinishers, small or large (from 400 till 1600 pieces per hour), manual operated, semi-automatic or full automatic. For the small budgets and for those that want to invest a little more.

For more information on the specific machine, and more picture, click on the Number in the title to go to the page on our website.

|

|

| |

Jensen Tunnelfinisher - Jenform 304 - STEAM - Nr 1792

|

|

| |

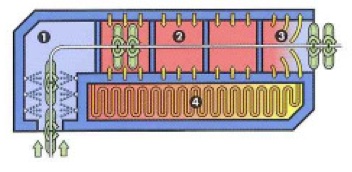

This steam heated tunnelfinsher is in very good condition, and is currently still running in the laundry. The machine and the system can be inspected in working condition. The system Includes 1 Metrifeed feeding station and an easy and selfsupporting transport system. The steam battery of the tunnelfinisher has been renewed in 2006.

Although the machine has been built in 1997, it almost looks like new. It has been maintained very well.

The capacity of the finisher is rated at 400 pieces per hour. The length of the machine is less than 3500mm, so it fits in almost any laundry.

|

|

|

|

| |

|

|

|

|

| |

Jensen Tunnelfinisher - Jenform Swiss 212 - GAS - Nr 2583

|

|

| |

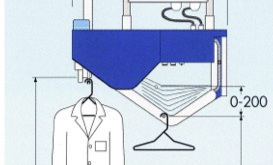

This Gas heated tunnelfinsher is in very good condition, built in 1999, and maintained very well. It comes with 2 metricon feeding stations to facilitate the feeding of the garments. The Metricon feeders are in height adjustable by 200mm, to adapt it according to the operator.

At the back end of the tunnelfinisher, the garments are transported to a Kannegiesser FAX 900 Garment folder from 2005.

The rail system has completely be renewed in 2005, at the time the garment folder was installed. The reason why this system has been sold is re-organization of the laundry.

|

|

|

|

| |

|

|

|

|

| |

Jensen Tunnelfinisher - Jenform Swiss 202 - GAS - Nr 2742

|

|

| |

A similar Gas heated tunnelfinsher, as the one above came out of a laundry which re-organized and decided to discontinue garment processing.

The machine is in very good condition and was built in 2001.

Depending on the requirements of the client, we can combine this system with a Metricon System from 2006, with 3 feeding stations and transport to an automatic or semi-automatic garment folder.

|

|

|

|

| |

|

|

|

|

| |

Kannegiesser Tunnelfinisher - MMT-2 Steam CV/D2-Y - Nr 2726

|

|

| |

This Kannegiesser Steam heated tunnelfinsher has been built in 1997, but still is working fine, and was maintained very well.

The machine is designed to process about 800 garments per hour.

2 Kannegiesser feeding station come with the system. It also can be combined with a semi-automatic garment folder if desired.

|

|

|

|

| |

|

|

|

|

| |

Kannegiesser Tunnelfinisher - HMT-400 Steam - Nr 2365

|

|

| |

For the small budgets and the small volumes, this Kannegiesser Steam heated tunnelfinsher is an ideal solution. It is very easy to operate. It used 3 settings, between which can be switched easily.

The finisher comes with with one feeding station, and can do up to 400 pieces and hour, so ideal for a laundry that does not have big garment volumes.

This also means that the system is compact, does not take a lot of floorspace, and is inexpensive to install.

|

|

|

|

Garment Folders

|

|

| |

Jensen Butterfly Maximat - Nr 2083

|

|

| |

This Jensen garment folder is from 2002 and in very good condition. The folder is semi-automatic, which means that feeding of the machine is manual.

The Maximat is equiped with a knife in the cross fold section, which allows also thick pieces from being folded.

Several types of garments can be folded, shirts, trousers and overalls.

An automatic stacker is integrated in the machine.

|

|

|

|

| |

Jensen Butterfly Minimat - Nr 2561

|

|

| |

From this Jensen Garment folder type, we have 2 pieces available. Both from 1996. The machines are fully automated and can be integrated with the tunnelfinishing system.

They have only one sorting. The garment can be automatically fed into the folder.

The capacity per machine is about 800 pieces per hour. Several types of folding are possible. The minimum piece length is 400mm, the maximum is 1600mm

The folder has a CT1083 operating panel.

|

|

|

|

| |

Jensen Butterfly Compact Uniform - Nr 1793

|

|

| |

The Jensen butterfly compact is an ideal machine for semi-automatic garment folding. The machine is fed manually, and has a small footprint.

This does not mean that the capabilities of the machine are limited. It can fold shirts, T-shirts, trouwsers, overals and workwear.

In addition, the folder can also be used as a towel folder. The machine has been manufactured in 1997.

|

|

|

|

| |

Kannegiesser FAX-900 - Nr 2584

|

|

| |

Full automtic Kannegiesser Garment folder, with in total 4 sortings, which facilitates the treating of different garments for the same customer.

The machine is buitl in 2005, and has a capacity of about 900 pieces per hour.

The special arrangement of the shaft in relation to the transport belt guarantees a positive adaptation to differing garment article thicknesses, i.e. from a thin patient gown to a heat resistant suit.

The articles are positively guided from top to bottom during the entire throughfeed. The article never runs unguided.

|

|

|

|

| |

|

|

|

|